Suitable Sonixtek Ultrasonic Cleaners for your Automotive Components

While Sonixtek offers a variety of ultrasonic cleaners, those with larger capacities, enhanced features, and robust construction are especially fitting for the rigorous demands of the automotive industry. Models with large tanks are precious for cleaning more significant automotive parts such as carburetors, fuel injectors, and various engine components.

The ST series is suitable for sporadic ultrasonic cleaning of engine parts. However, we recommend using a unit equipped with a filtration pump for routine cleaning components such as engine parts, carburetors, turbos, filters, and entire engines. This approach significantly reduces operating costs by extending the detergent solution and promoting environmental sustainability.

The SF, UMX, AL, and AU Ultrasonic Cleaners offer a filtration system. While the SF units use easy, operable manual buttons, the UMX models boast a user-friendly interface with tactile buttons and a vibrant color display. The AL and AU units come with a sizeable 7-inch touch screen, which allows you to customize and save cleaning cycles, adjust factors such as cleaning duration and temperature, and conveniently load these presets as needed.

For those who frequently clean bulky items or simultaneously handle multiple automotive components, a lifting platform unit is ideal. All units in the AL and AU ranges feature this option and can load objects up to 2000kg. This feature simplifies the loading and unloading process and incorporates an agitation function, enhancing the overall cleaning efficiency.

Features and Their Benefits

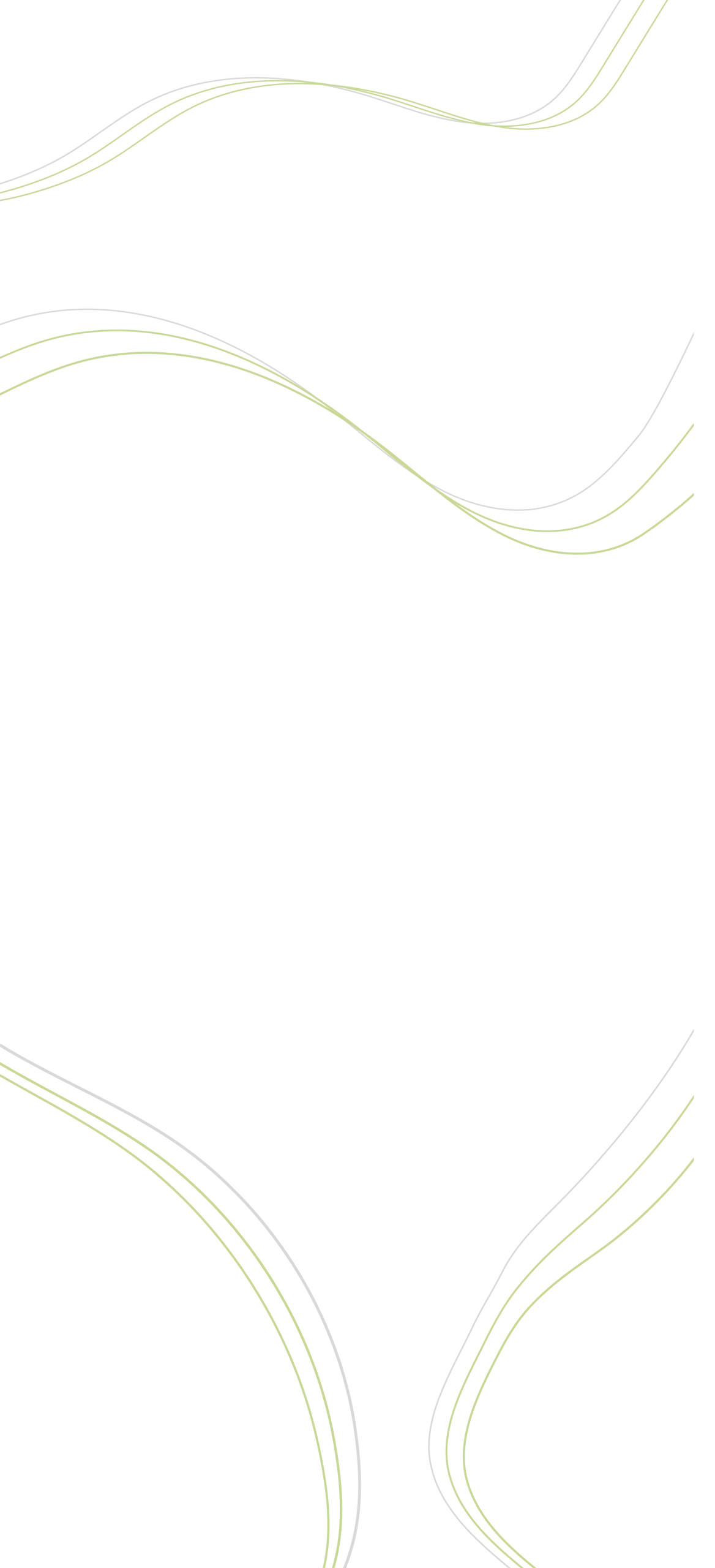

Programmable Cycles for UMX and AU Series

Benefits: The ability to program cleaning cycles offers unparalleled convenience. Moreover, different automotive parts may require varied cleaning durations and intensities. With programmable cycles, users can set and save specific cleaning routines for different parts. Consequently, this ensures consistent results and prevents damage that can arise from over-cleaning.

Touch Screen

Benefits: A modern touch screen interface simplifies the operation, offering an intuitive experience even for those unfamiliar with ultrasonic cleaners. Additionally, it allows for easy setting adjustments, program selection, and real-time monitoring of cleaning processes.

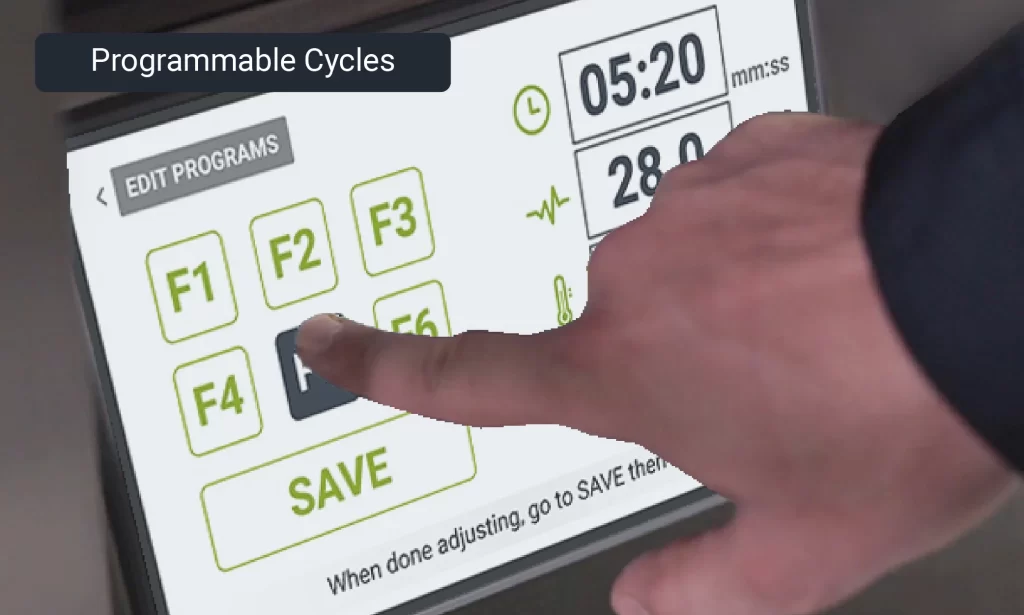

Agitation Function

Benefits: The agitation function ensures the cleaning solution is constantly in motion, which can dislodge particularly stubborn contaminants. Agitation is especially beneficial for automotive parts with complex geometries or those that have accumulated heavy grime over extended periods.

Loading Platform

Benefits: A loading platform simplifies placing and retrieving items from the cleaner. This feature is a boon for heavy or awkwardly shaped automotive components, reducing the risk of injuries and ensuring that the parts receive correct positioning within the tank for optimal cleaning.

Filtration System

Benefits: Over time, the cleaning solution can contaminate the grime meant to eliminate. A filtration pump tirelessly circulates and filters the solution, ensuring its prolonged effectiveness. This enhancement in cleaning outcomes reduces the need for frequent solution replacements, ultimately leading to cost savings.

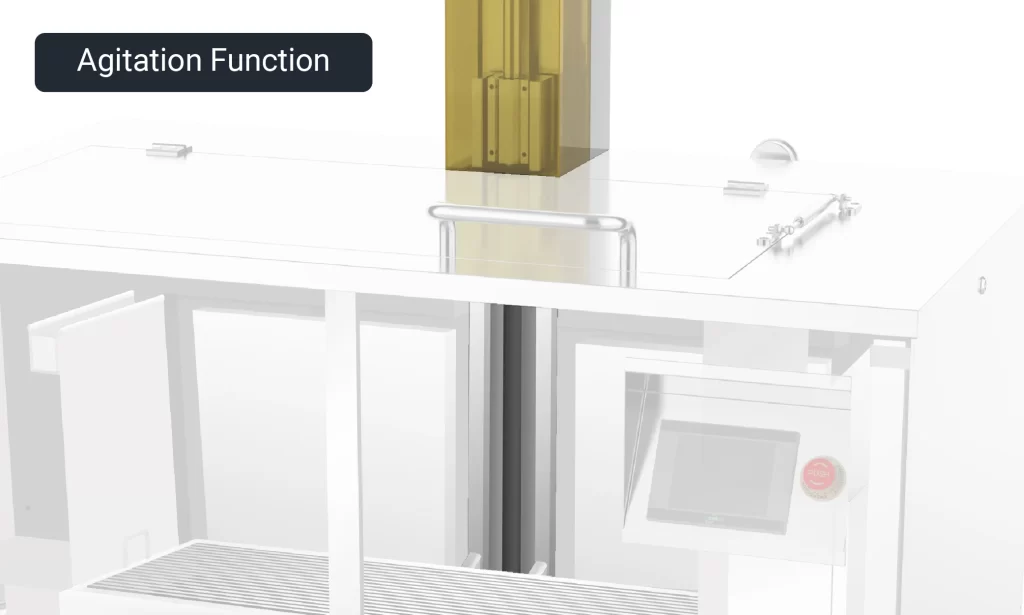

Oil Skimmer/Separator

Benefits: Automotive Ultrasonic Cleaners are practical tools for cleaning automotive parts, particularly those from engines or transmissions that can become coated in oil or grease. An integrated oil skimmer or separator removes these oils from the cleaning solution. This maintains the efficacy of the cleaning solution and ensures that the parts emerge from the process oil-free.

In conclusion, choosing the right ultrasonic cleaner for automotive industrial demands can greatly affect efficiency and results. By researching, assessing your demands, and purchasing a high-quality ultrasonic cleaner that meets your objectives, you may boost production, part quality, and automotive industry results.

For other Sonixtek news and updates, follow Sonixtek Facebook Page.