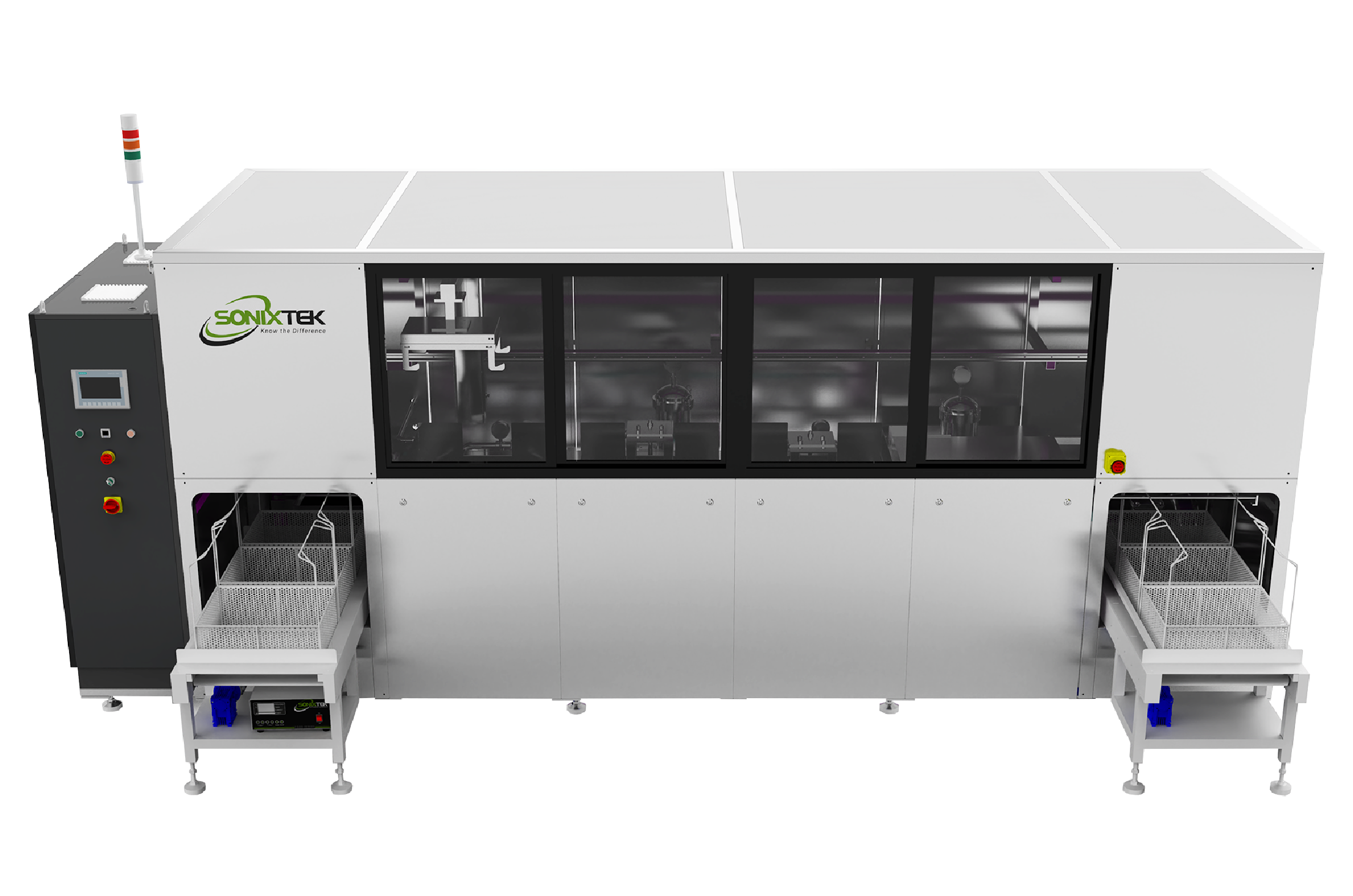

The Sonixtek Automated Line Series 75L is an automated industrial ultrasonic cleaner designed to be used in the most demanding industrial environments where powerful cleaning is required.

The heavy-duty equipment offers full customization and, furthermore, features multiple tanks for seamless ultrasonic cleaning, bubbling, rinsing with agitation, and drying.

This range serves all industrial processes, including power and heat plants, garages, mechanical industries, electronic workshops, aerospace component manufacturing, weapon manufacturing, chemical processing industries, manufacturing industries, and more.

The Sonixtek Automated Line Series 75L integrates numerous innovative and state-of-the-art functions controlled by a 24 IO Siemens PLC and 10 to 19-inch Siemens touchscreen with the capability for remote analysis and problem identification either via a wired or a wireless secure network over the internet.

The comprehensive operation offers numerous options and settings via the touch screen, such as a PLC-controlled water flow system, an agitation function, a lift system with a precision motor, multi-temperature sensors that monitor the temperature in the tank, an automatically controlled fill system, water level sensors, an automatic lid, etc.

Caractéristiques du produit

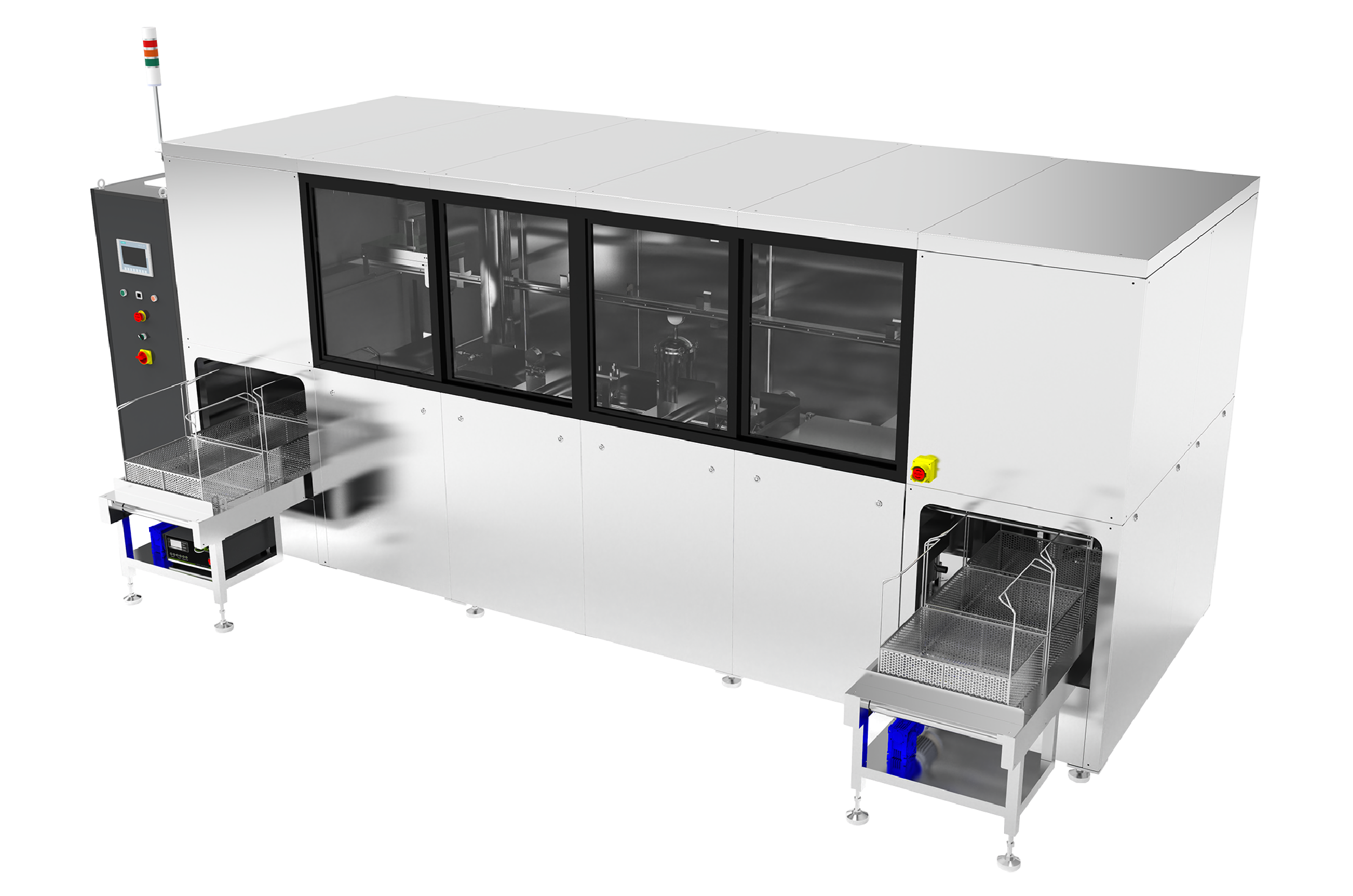

- Automated basket handling by servo motor-controlled system

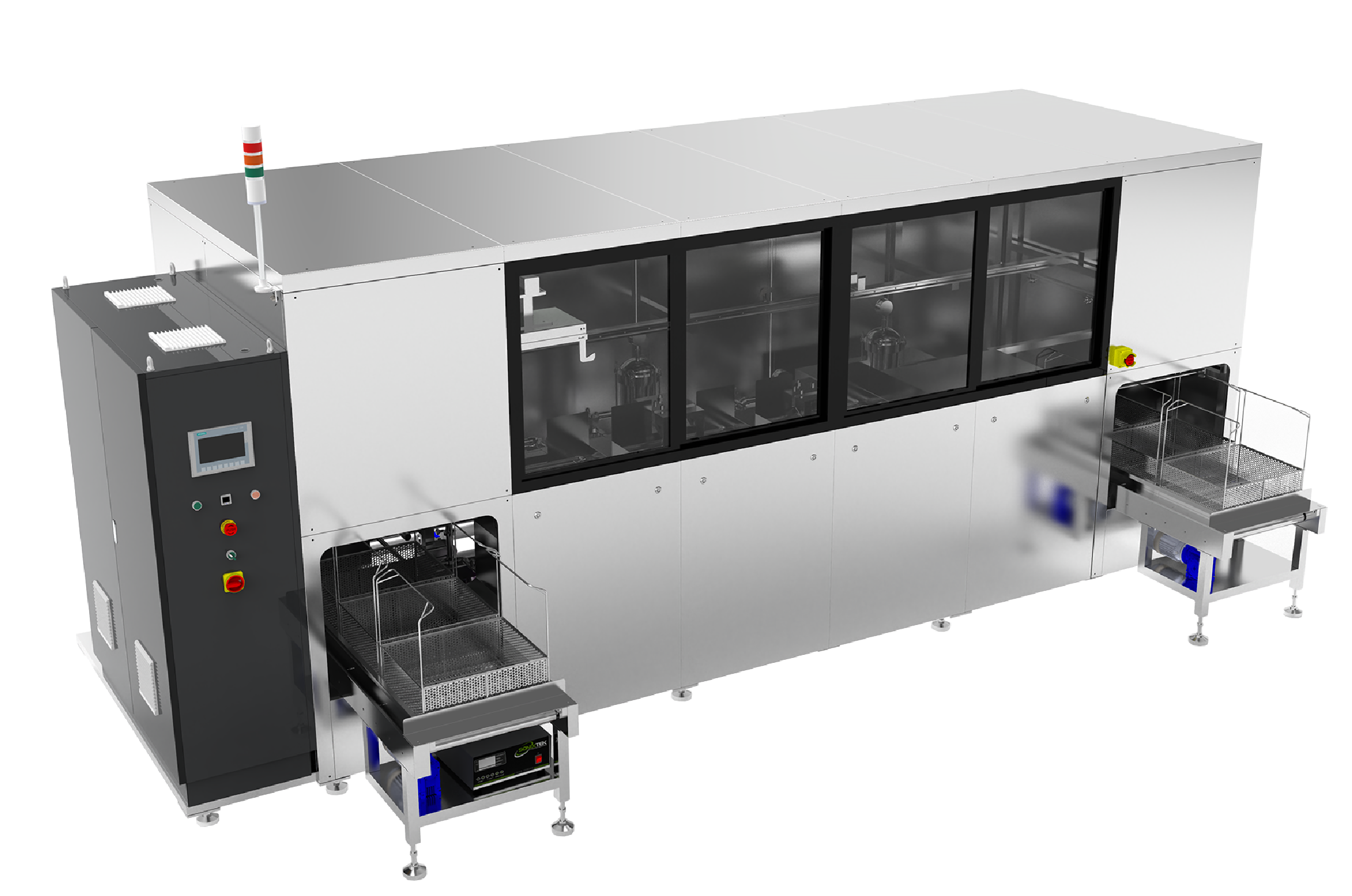

- Multistage stage Filtration system with multiple filtration levels

- Pneumatic actuated platform with agitation

- Laminar flow system

- External control cabinet

- Powerful air bubble cleaning tank

- Rotating high-pressure jets cleaning

- Oil skimmer and oil separator systems

- Auto-dosing detergent system

- Multi-frequency ultrasonic transducers and generators

- Distillation through reverse osmosis for water recycling and purification

- Automatic feeding and discharging basket with barcode selection

- Fully automatic operation and real-time monitoring on screen or remote IP network

- Stainless steel acid and alkali resistant in AISI304, AISI316 or Duplex

- Dry system with swing mechanism and rolling mechanism

- Heating and chiller system

- Filtration, distillation and reverse osmosis system

- Multi-IO Siemens PLC with remote IP connection

- 10″ – 19″ touch screen

- Stack light indicator with alarm

- Barcode scan option for automated selection cleaning cycles

- Each tank is independently controllable (cycle time, temperature, etc.)

Spécifications du produit

| Capacity | 75 liters |

| Dimensions du réservoir* | 500mm x 530mm x 600mm |

| Useful Tank Dimensions* | 500mm x 400mm x 370mm |

| Dimensions extérieures* | 494mm x 168mm x 205mm |

| # de transducteurs | 20 |

| Puissance ultrasonique (Watt) | 1200 |

| Puissance de chauffage (Watt) | 4000 (single tank) |

| Heating Temperature | Ambient: 100°C |

| Power Supply | 400V |

| Fréquence de travail | 40 kHz, 80kHz |

* – All dimensions are indicated as Length x Width x Height (=Width x Depth x Height) in mm